Few components of a car are as quietly very important - or as quite often lost sight of - as its glass. Windshields, area windows, and rear glass have shaped no longer merely the motor vehicle’s appear yet additionally its defense tale. The avenue from brittle plate glass to right now’s multi-layered, repairable windshields is a story full of trial, errors, and ingenuity. Understanding how automobile glass repair advanced through the years well-knownshows simply how a whole lot craftsmanship and science now cross into what would possibly look like a essential restore for a chipped windshield.

Early Days: Plate Glass and Its Perils

The first vehicles wore their glass basically like jewelry: skinny panes set into brass frames, delivering little greater than defense from bugs and wind. Until round 1920, maximum motors used basic plate glass - the same sort found out in buildings at the time. It become clean sufficient to see because of however unforgiving beneath strain. Even a modest stone may just crack it; in collisions, plate glass shattered into damaging shards that most commonly prompted extra injury than the coincidence itself.

People didn’t fix vehicle glass then. If you broke it, you changed it - assuming you bothered in any respect. Some early drivers with ease got rid of cracked panes rather than pay for brand new ones. The idea of fixing a chip or crack wasn’t on everyone’s radar.

Laminated Safety Glass: A Turning Point

Everything modified in 1927 while Ford began fitting laminated safety glass as everyday gadget in a few units. This innovation sandwiched a thin plastic layer (broadly speaking cellulose nitrate or cellulose acetate) among two sheets of glass. A rock may just still chip or crack it, however the internal layer held the fragments jointly, decreasing the hazard of injury.

Laminated glass modified both protection and repair selections. No longer did each ruin mean entire replacement. Minor chips usally stayed contained in the outer layer, distinctly with careful driving and activate consideration.

Yet maintenance were nonetheless uncommon. Most frame retail outlets lacked gear or tactics to cope with some thing past complete substitute. Insurance prone not often protected chipped windshields unless they threatened vision or structural integrity.

The Rise of Tempered Glass

While windshields went laminated for safety, many facet and rear windows switched to tempered glass by way of mid-century. Tempering entails heating widely used glass to high temperatures previously right now cooling it, growing interior stresses that make it more difficult opposed to widely wide-spread affects.

Tempered glass resists small chips bigger than historic plate forms yet shatters wholly below drive - famously breaking into tiny cubes instead of sharp shards. It’s safer in an coincidence yet inconceivable to repair once damaged; replacement remains the solely preference if broken.

Windshields persisted as a result of laminated creation as a result of rules demanded each visibility after influence and resistance to ejection for the time of crashes.

Birth of Modern Windshield Repair

The precise evolution in vehicle glass restoration began in earnest right through the Nineteen Seventies oil quandary. Rising gas fees made laborers dangle onto automobiles longer, sparking call for for cost effective fixes that avoided pricey replacements.

In 1971, Dr. Frank Werner patented one of many first life like windshield chip restoration techniques within the United States. Using clear resin injected into small cracks and chips less than vacuum power, his strategy restored force and more desirable readability without hunting down the whole pane.

This invention converted expectations in a single day:

- Windshield chip restoration become possible for spoil up to approximately an inch throughout. Drivers now not needed to stay with distracting blemishes or fork out for replacement at every ding. Insurance firms warmed as much as overlaying maintenance in place of footing some distance increased expenses for new windshields.

Early resin formulas cured slowly and often times yellowed over the years, distinctly lower than good solar. Yet even this imperfect answer marked a bounce forward when compared to pre-fix days.

How Techniques Improved Over Time

As autos evolved - curved windshields became average by way of the overdue 1970s - so did calls for on restoration strategies. Technicians faced new demanding situations: matching tricky contours, facing tinted layers or embedded antennas, maintaining integrated sensors like rain detectors or lane-departure cameras.

Resin formulations grew clearer and greater thru chemical engineering advances inside the Nineteen Eighties and beyond. UV-curing lamps minimize hardening occasions from hours to minutes although improving transparency significantly.

Repair gear also evolved:

- Early kits relied on manual pumps; cutting-edge techniques use properly vacuum injectors. Multi-level cleansing routines lowered infection which could cloud repairs. Temperature controls enable techs work 12 months-round with out sacrificing high-quality.

For example, I don't forget my first run-in with a celebrity-fashioned chip on a targeted visitor’s 1988 Buick LeSabre windshield in the time of an icy February morning in Chicago. The bloodless not easy every part - resin thickened too shortly if now not pre-warmed effectively, making clarity rough to acquire. With right this moment’s temperature-controlled kits, that task may take 0.5 as long with stronger outcomes.

What Makes a Good Repair?

Not each and every chip shall be fixed equally good; factors like size, depth, situation, filth intrusion (and many times driving force impatience) choose results more than any unmarried product claim does.

A well-achieved windshield chip restore restores approximately ninety% of optical clarity when regarded straight-on - satisfactory that maximum drivers omit wherein spoil once become after per week in the back of the wheel. Structurally speaking, injecting resin halts further cracking through redistributing rigidity alongside microscopic fissures within laminated layers.

But there are limits:

If a crack runs longer than about three inches (every now and then less), resin on my own should not steer clear of spreading across bumpy roads or thermal swings. Repairs close to sensor clusters need unusual care to circumvent interfering with electronics. Dirt trapped within antique chips makes most appropriate readability unattainable; well timed movement concerns more than maximum realise. Many technicians have warfare stories approximately tried “fixes” gone fallacious whilst house owners waited months sooner than searching for assist or tried DIY kits that left cloudy spots at the back of.

A Quick Guide: When Repair Works Best

Most professionals have faith in these principles-of-thumb until now making an attempt windshield chip repair:

Damage smaller than 1 / 4 (about one inch) responds best possible. Cracks shorter than 3 inches could also be stabilized if taken care of at once. Chips out of doors direct line-of-sight pose fewer optical complications after repair. Laminated windshields most effective; tempered area/rear windows cannot be repaired safely. Cleanliness counts: more energizing chips yield clearer consequences due to less grime/water intrusion.Shifting Standards: From Artisan Craft To Everyday Service

What started as whatever equivalent to wizardry (and in general reserved for prime-end cars) progressively became mainstream across the Nineteen Nineties and early 2000s as either public know-how and insurance rules caught up with science.

Shops commenced equipping vehicles with moveable restoration rigs; technicians realized hints for adapting resin viscosity based totally on weather conditions or matching tint shades for luxury versions from BMW or Lexus.

By around 2010, national chains marketed same-day telephone provider that may restoration maximum cracks curbside at domicile or work without doing away with your auto from service for lengthy spells.

Regulations & Insurance Drive Adoption

One unsung hero at the back of enormous adoption become the assurance market itself: seeing facts displaying maintenance rate less than complete replacements by means of an order of significance (continuously $50-$a hundred in line with restoration as opposed to $four hundred+ in step with new windshield), many insurers waived deductibles solely while shoppers chose certified maintenance over replacements.

Regulatory bodies joined in too:

- U.S Federal Motor Vehicle Safety Standards set minimum requisites for driver visibility publish-fix. European Union policies harmonized standards throughout borders so drivers might go back and forth between countries devoid of authorized headaches over repaired windscreens.

These steps helped build have faith between motorists who’d formerly worried approximately “patched” windshields failing inspection or resale tests down the line.

High-Tech Glass Brings New Challenges

Today’s car glass isn’t just clearer or more desirable; it’s smarter too - bristling with embedded sensors for rain detection, heads-up reveals projecting pace right now onto your viewline, warmers woven into cut back edges against frost buildup.

All those positive aspects complicate even basic maintenance:

A technician ought to title whether any electronics run shut under visible chips until now drilling or injecting resin lest they brief out sensitive wires. Repairs have got to restoration optical clarity now not just for human eyes but additionally for lidar sensors used by complex motive force-assistance strategies (ADAS). Calibration routines after paintings ensure that lane-departure cameras stay properly publish-restore.

For example: Several years in the past I tackled a minor bullseye chip accurate where a heated wiper park detail ran below the floor on a Subaru Outback windshield. Careful mapping earlier let me forestall dangerous invisible filaments hidden within layers I couldn’t see straight however knew had been there from organization specs.

Modern preparation now incorporates modules on ADAS calibration and secure coping with practices round excessive-voltage parts determined close electric powered auto glazing.

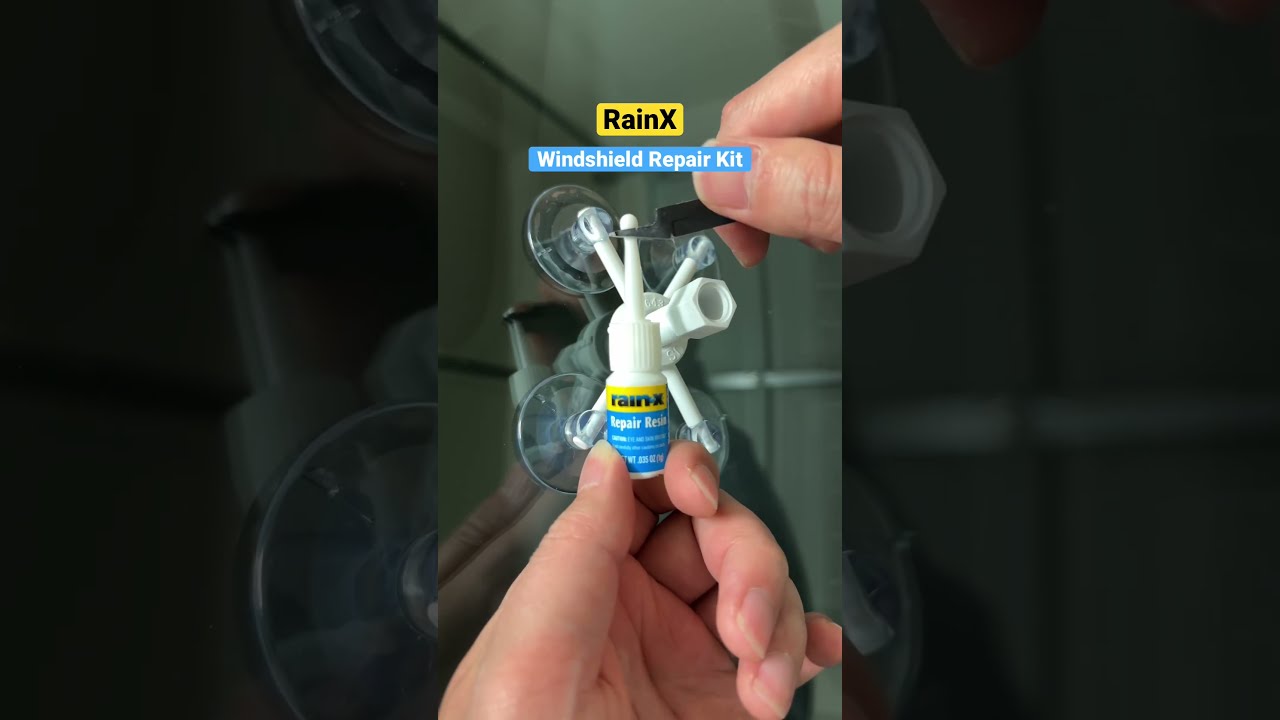

Do-It-Yourself Kits vs Professional Service

With vast-container stores stocking DIY chip-fix kits promising fast fixes for $15-$25 apiece, many ask yourself no matter if calling a seasoned makes sense anymore.

DIY answers can stabilize very contemporary damage if handled conscientiously by way of an individual sufferer sufficient to comply with recommendations precisely:

Clean facet properly employing furnished razor blades/alcohol pads. Apply supplied bridge/injector assembly established exactly over spoil factor. Inject resin the use of hand plunger until eventually cavity fills entirely (seem to be carefully from exclusive angles). Cure under UV lamp/sun in keeping with kit classes devoid of moving assembly in advance. Scrape away excess cured resin gently after removing.Still, pros convey significance beyond just supplies:

Skill at judging which ruin versions will yield desirable consequences, Access to business-grade resins/curing gear, Experience operating around embedded sensors/electronics, Warranty protection if a specific thing is going incorrect later, Documentation wide-spread by means of insurers/dealerships all over resale/exchange-in inspections.

I’ve noticed a couple of enthusiastic DIYer leave permanent blur marks lifeless-midsection on highly-priced panoramic roofs because air bubbles trapped inside of not at all worked their manner out earlier curing carried out.

Sustainability Matters Too

Repairing in place of replacing saves more than money: every refrained from substitute manner much less waste despatched to landfills (a typical contemporary windshield weighs among 25–40 kilos). Recycling previous car glass continues to be tough simply by laminates/plastic videos fused inner most panels.

Some shops collect scrap cloth for specialized recycling facilities in a position to separate layers chemically as opposed to sending every part immediately into dumpsters.

Plus there’s strength stored warding off manufacture/shipment/deploy cycles required via new OEM parts.

Cumulatively across tens of millions of vehicles every 12 months around the globe this provides up: estimates mean trendy adoption of windshield chip fix prevents 1000s of an awful lot of needless landfill once a year.

What Lies Ahead?

As automakers retain integrating ever more technology into auto glazing - consider augmented certainty overlays projected promptly onto your area-of-view or clever sensors monitoring cabin air caliber because of micro-perforations - long term upkeep will simplest grow more complex.

Expect ongoing advances in resin chemistry tailored peculiarly for ultra-clear optics appropriate with next-gen heads-up screens.

Training standards will increase in addition so techs can interface seamlessly with linked car window replacement Aberdeen, motor vehicle diagnostics submit-restore.

There would come an afternoon while specified damages are self-recognized by your personal automotive alerting you as a result of dashboard message previously you even notice them yourself.

Whatever comes next although one factor looks bound: provided that there are rocks on highways and motors zipping prior trucks full of free gravel skilled fingers armed with competencies will stay searching approaches to store proper glass from useless waste - restoring either serve as and peace-of-brain mile after mile.

Word Count: ~1,750